Know on a daily basis that your assets will be available and reliable.

Overview

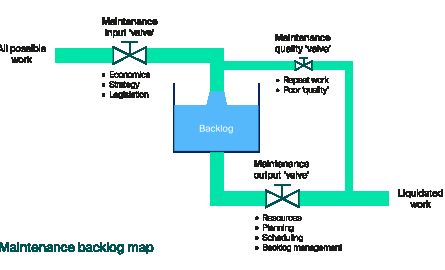

Using proven methods on a quantified-risk basis, we’ll help you optimise preventive maintenance tasks, minimise backlogs and safely extend asset life. You can focus on the most effective activities and timeframes for these.

Working closely with you, our engineers will unlock the history from within your maintenance management systems, identifying key reliability data.

Operators across all process industries can benefit, be that fixed and floating oil and gas production facilities, onshore refineries or power & chemical plants.

Track record

For decades we’ve helped businesses maintain and manage their assets globally, driving down operational costs and optimising efficiencies.

Services

- Master equipment list verification and population

- Structuring functional asset hierarchy

- Allocating ISO14224 based equipment types and failure codes

- Equipment criticality analysis

- Failure modes and effects analysis (FMEA)

- Maintenance management optimisation

- Reliability improvement studies, planning and implementation

- Root cause analysis (RCA)

- Preventative maintenance (PM) optimisation studies

- Reliability centred maintenance (RCM)

- Spare parts optimisation